Car park concrete needs protection

Whether basement or above ground, car park concrete is under a high level of situational stress. Traffic load and abrasion; carbonation from exhaust fumes; exposure to moisture-borne contaminants carried in by tyres; and for roof decks, total exposure to the weather.

The result is that these structures seem to have a comparatively high need for remediation treatments – crack repair or more.

Let’s talk about underlying causes

Concrete deterioration, other than structural failure or movement, can almost entirely be linked back to one source: moisture-borne contamination.

Concrete is innately porous, despite everyone’s best efforts. This is because water, escaping during the curing stage, creates bleed pores and avenues through the concrete.

Avenues for moisture

These pores become an avenue for moisture back into the concrete; and moisture carries dissolved reactants such as chlorides or sulphates, encouraging chemical reactions in the concrete plus corrosion of the reinforcing steel. The resulting cracks exacerbate the issue – a cycle of premature deterioration has begun.

That’s a very simplistic overview, and there’s usually more than one element of deterioration occurring at a time.

Let’s talk about timely maintenance

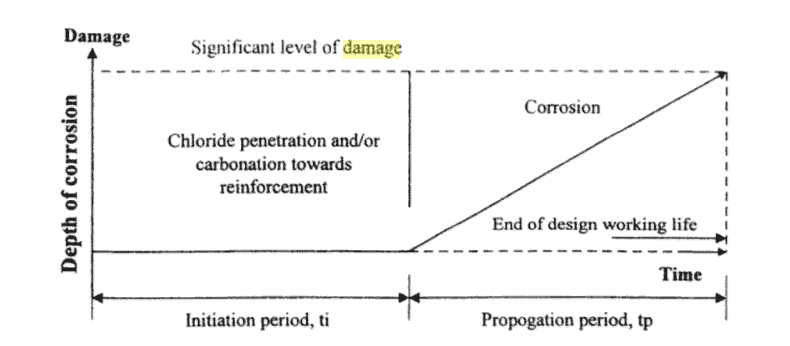

There’s a very helpful diagram originated by Kyösti Tuutti of Lund University, Sweden, that illustrates the urgency of dealing with deterioration. Here’s a simple version, showing the initiation phase and the ‘propagation’ deterioration phase. Notice that at the final point, the structure has ended its working life.

And now, let’s talk about an effective response

There is an advanced solution. Penetrating nanoparticle colloidal silica treatments are available to arrest the deterioration and extend that service life – if applied early. With this in mind, we’ve modified the graph slightly, to demonstrate that if treatment is applied in the initiation phase – that’s well before the damages are severe or obvious – then the service life can be significantly extended.

Think about what this means for long-term cost savings!

Immobilise moisture!

MARKHAM colloidal silica treatments immobilise moisture, converting it to a hydrogel within the porosity of the concrete. This prevents the entrance of movement of moisture – and moisture-borne contamination.

These hydrogel treatments can become key to cost-effective pro-active maintenance.

Hydrogel treatments can also assist as part of remediation works, sealing cracks up to 0.5mm, preventing incipient anode formation, and enhancing the longevity of the repairs.

We invite you to find out more or to discuss your current concrete maintenance challenges. Get in touch with our friendly team today!

To help you with car park and transportation structures, we’ve set up a dedicated industry page.

Why not spend a few minutes with our on-demand webinar, “Adding Life to Ageing Structures“?